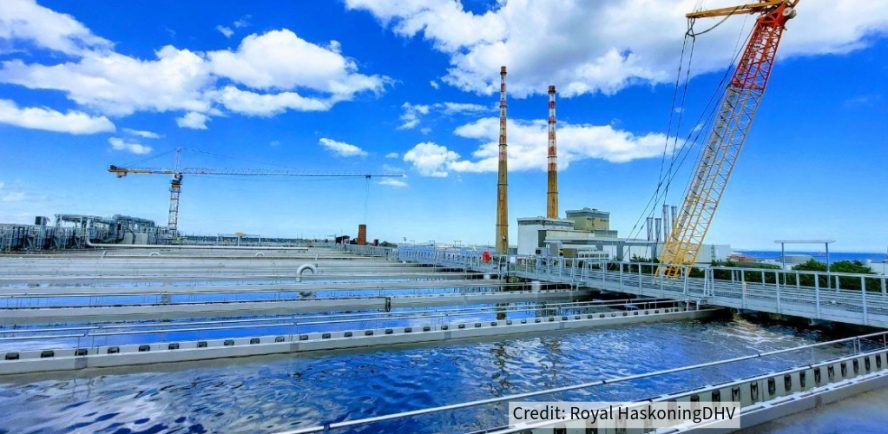

Ringsend SBR Retrofit Contract – Block 2

Ringsend, DublinIn September 2021, Celtic Anglian Water Ltd (CAW) with partners TES Technologies and Farrans Construction, trading as the FaCT3 Consortium, secured the SBR Block 2 Retrofit Contract at the Ringsend Wastewater Treatment Plant— one of four major Upgrade Contracts being procured by Uisce Éireann to enhance the secondary treatment at the Ringsend Plant, which serves the greater Dublin area.

The Block 2 Retrofit Contract award coincided with the successful completion of the first Upgrade Contract, SBR Retrofit Contract – Hybrid Package I, again, delivered by the FaCT3 Consortium. The planned upgrades will boost capacity and treatment standards at the Ringsend Wastewater Treatment Plant, expanding the treatment capacity from 1.64m PE to 2.4m PE and improving treatment effluent standards to meet the 2010 Urban Wastewater Treatment Directive.

The project took 27 months to complete and was delivered on time and within budget. The FaCT3 Project Delivery Team worked in partnership with Uisce Éireann and the Block 2 Contract was delivered under the 16-030 Major MEICA Framework which embraces and promotes a collaborative partnership approach between all parties. The Block 2 Retrofit Contract included inter-alia, the largest over-pumping exercise in Ireland, where the team collaborated to divert flow in order to avoid overflow of the storm tanking during isolation of one of the ILPS sump chambers for an extended period during essential works.

Project Scope

The Block 2 Contract required the retrofit of four Sequential Batch Reactor (SBR) cells in Block 2, one of three of the upper deck SBR Blocks to enable a portion of the settled wastewater arising at the Ringsend plant to be treated to a secondary/tertiary standard using a patented Aerobic Granular Sludge (AGS) – Nereda® process technology.

Project delivery

As part of this Contract, the FaCT3 Consortium successfully delivered:

- A phased retrofit of the High Lift Pumps serving all of the 3 upper deck SBR Blocks located in the Intermediate Lift Pumping Station (ILPS);

- Phased retrofit of the existing Aeration system manifold pipework serving the upper deck SBRs;

- Modification to Block 2 centre core and provision of inlet and selection shafts for Block 2;

- Retrofit of Block 2 (Cells 2A, 2B, 2C and 2D) with AGS Nereda® technology equipment;

- Provision of Sludge Buffers and Water Level Correction (WLC) Buffers within Block 2;

- Electrical and Instrumentation, Control and Automation equipment;

- Metal Salts Dosing and associated distribution system;

- Odour Control Treatment and associated collection system;

- Miscellaneous associated items including SAS Discharge, Washwater Utility, Compressed Air, Hoisting Facilities, Drains etc.

Upon completion of the construction phase the retrofitted AGS Cells and High Lift Pumping Station successfully completed a 28 day performance Trial before entering into operational service. In addition to being an integral member of the FaCT3 Consortium delivering the Block 2 Retrofit Contract, CAW is the Existing Operator of the Ringsend WwTP and continues to manage the operation and maintenance of the 4 No. Nereda® AGS retrofitted Block 2 Reactor Cells.

A collaborative framework

The Block 2 Retrofit Contract was delivered under the Uisce Éireann 16-030 Major MEICA Collaborative Framework which promotes a collaborative and teamwork culture between all of the four contract main delivery partners, the FaCT3 Consortium, Uisce Éireann (the employer), the 3JV (the Employer’s Representatives) and CAW as the Existing Operator.

Overcoming challenges with an innovative approach – leading to a record over-pumping operation

The project required five new High Lift Pumps serving all three of the upper deck blocks to provide direct pumping to the SBR cells. As part of the M&E installation, each pump was installed into a specific Wet Well Chamber which had to be isolated via the insertion of stop-logs into the existing frames at the inlet to each chamber. This allowed the pumps to be installed into a “dry well”, ensuring that operational flows from the ILPS could be maintained without interruption of flow to the secondary treatment stage.

This was straightforward for four of the existing High Life Pump Chambers that already had stop-log frames. However the fifth did not, so it was necessary to fit a stop-log frame prior to installing the High Lift Pump No.5.

The safe installation of the stop-logs frame into High lift Chamber No.5 required isolation of the ILPS sump chamber for an extended period of 10 hours. Diversion of flows to the 60,000m3 capacity storm tanks would typically allow a maximum of 4 hours working window.

The extension of the working window to 10+ hours required significant collaboration between the FaCT3 Consortium and CAW as the Existing Operator.

To reduce the flowrate to the storm tanks during the works and to mitigate against any untreated discharges to the sea, CAW implemented a major over-pumping exercise on the Wastewater Treatment works. CAW controlled the overall flow from the Inlet Works through:

- the isolation of the ILPS sump using Stop-logs.

- the initial draining down of the ILPS sump using existing ILPS pumps.

- the installation and operation of 2m3/s over pumping from the Lamella Primary Settlement Stage outlet channel to the ILPS low level splitter chamber.

This over-pumping involved the installation and operation three 12” pumps powered by mobile generators, eight 8” submersible variable speed pumps and up to seven 8” diesel direct driven pumps. These collectively pumped 2m3/s from the Lamella Primary Settlement Stage outlet channel, bypassing the ILPS sump, to discharge into the low-level splitter chamber of the ILPS.

Water being diverted during the overpumping exercise

The over-pumping of flows over two days to bypass the ILPS sump chamber allowed for the completion of the full civil and mechanical works associated with fitting the new stoplog frame into High lift Chamber No.5 without storm discharges and without interruption to the incoming flows to the Ringsend WwTP. This is the largest over-pumping operation at a wastewater treatment plant in Ireland to date!